Manufacturing Engineering and Technology, 8th Edition by Serope Kalpakjian and Steven R. Schmid offers a comprehensive, balanced, and up-to-date coverage of manufacturing’s science, engineering, and technology.

Overview of the 8th Edition

The 8th Edition of Manufacturing Engineering and Technology provides a comprehensive, up-to-date resource for understanding manufacturing processes, materials, and technologies. It emphasizes interdisciplinary approaches, combining engineering, science, and practical applications. Updated chapters cover robotics, programmable logic controllers (PLCs), and industrial automation networks. The edition also integrates active learning techniques and digital tools to enhance student engagement. This balanced approach makes it a valuable resource for both students and professionals in the field of manufacturing engineering.

Key Features and Updates

The 8th Edition of Manufacturing Engineering and Technology offers enhanced coverage of robotics, programmable logic controllers (PLCs), and industrial automation networks. It includes updated chapters on modern manufacturing techniques and smart technologies. Active learning techniques, preview activities, and digital resources are integrated to improve student engagement. The edition also emphasizes sustainability and global economic considerations, providing a well-rounded perspective on manufacturing. These updates ensure the text remains relevant and aligned with current industry trends and challenges.

Manufacturing Processes and Materials

This section explores the fundamental materials and processes in manufacturing, including metals, polymers, ceramics, and composites. It covers mechanical behavior, testing, and their applications in production.

Traditional Manufacturing Methods

Traditional manufacturing methods encompass conventional processes such as casting, forging, machining, and joining. These techniques are foundational, relying on established practices and tools. Casting involves shaping materials by pouring into molds, while forging uses compressive forces to shape metals; Machining includes cutting and grinding operations to achieve precise dimensions. Joining methods like welding and fastening complete the assembly of components; These methods are widely used for their reliability and adaptability in producing standardized products.

Modern and Advanced Manufacturing Techniques

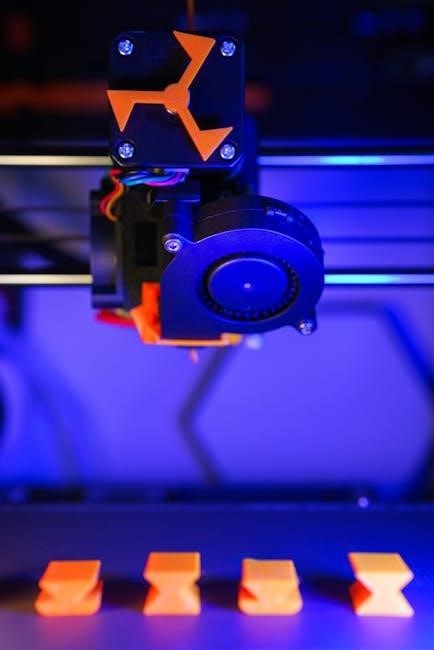

Modern manufacturing employs cutting-edge technologies like additive manufacturing, 3D printing, and CNC machining. These methods enhance precision, reduce material waste, and enable complex geometries. Additive manufacturing builds products layer-by-layer, offering design flexibility and rapid prototyping. CNC machining uses automated systems for high-accuracy parts. These techniques improve efficiency, reduce lead times, and support customization, making them integral to contemporary production processes and innovation-driven industries.

Automation and Robotics in Manufacturing

Automation and robotics transform modern manufacturing by enhancing efficiency, precision, and scalability. Programmable Logic Controllers (PLCs) and industrial automation networks enable seamless integration and control of production processes.

Robotics and Programmable Logic Controllers (PLCs)

Robotics and PLCs are integral to modern manufacturing, enhancing precision and efficiency. The 8th edition details their integration, with robotics optimizing production lines and PLCs enabling automated process control. Advanced applications include CNC machining and industrial automation networks. The text provides practical insights into programming and implementing these technologies, supported by case studies and exercises for hands-on learning, ensuring students grasp their role in contemporary manufacturing systems effectively.

Industrial Automation Networks and Their Applications

Industrial automation networks play a pivotal role in modern manufacturing by enabling seamless communication and control across production systems. The 8th edition elaborates on these networks, detailing their architecture and applications in real-time data exchange, process monitoring, and automated control. These networks enhance efficiency, reduce errors, and improve scalability. The text also explores their role in integrating robotics, PLCs, and IoT devices, providing practical examples of their implementation in smart manufacturing environments to optimize production workflows and ensure reliable operations.

Quality Control and Metrology

Quality control and metrology are essential for maintaining precision and accuracy in manufacturing. Engineering metrology ensures accurate measurements, while quality assurance processes guarantee reliable outcomes.

Engineering Metrology and Instrumentation

Engineering metrology focuses on precise measurements and instrumentation to ensure accuracy in manufacturing processes. It involves dimensional metrology, surface finish measurement, and geometric tolerancing. Advanced instruments like coordinate-measuring machines (CMMs) and laser scanners are used for precise inspections. These tools are critical for maintaining quality and consistency in production. The 8th edition emphasizes the role of metrology in modern manufacturing, highlighting its integration with quality control systems to optimize production efficiency and adherence to standards.

Quality Assurance, Testing, and Inspection

Quality assurance ensures products meet specified standards through systematic testing and inspection processes. The 8th edition emphasizes statistical quality control methods and advanced inspection techniques. It covers non-destructive testing methods like ultrasonic and radiographic testing, ensuring product reliability. Automated inspection systems, including machine vision, are highlighted for their role in improving accuracy and efficiency. These practices are essential for maintaining high-quality outputs and reducing defects in modern manufacturing environments.

Design for Manufacturing and Assembly

Design considerations significantly impact production efficiency and costs. This section explores principles and guidelines for designing products that minimize production costs and enhance reliability.

Design Considerations and Their Impact on Production

Design considerations play a crucial role in production planning, influencing cost, efficiency, and product reliability. Effective design minimizes production costs while enhancing manufacturability and sustainability. By optimizing material selection, tooling requirements, and assembly processes, designs can significantly reduce production complexity. This section emphasizes the importance of integrating design with manufacturing processes to achieve lean production and operational excellence, ensuring products meet quality and performance standards while addressing environmental and economic challenges.

Human-Factors Engineering and Product Liability

Human-factors engineering focuses on designing systems to enhance safety, efficiency, and user experience, reducing errors caused by human-machine interactions. Legal and ethical considerations tie into product liability, emphasizing the manufacturer’s responsibility for ensuring safety and functionality. This section explores ergonomic design principles, workplace safety standards, and the legal implications of product design, ensuring manufacturers meet regulatory requirements and minimize risks associated with product use and production environments.

Emerging Technologies in Manufacturing

Additive manufacturing and smart manufacturing are transforming the industry, enabling rapid prototyping, increased precision, and enhanced efficiency through advanced technologies like 3D printing and Industry 4.0.

Additive Manufacturing and 3D Printing

Additive manufacturing and 3D printing revolutionize production by enabling layer-based creation of complex geometries, reducing material waste, and allowing rapid prototyping. These technologies facilitate customization, enhance precision, and streamline production processes. Applications span industries like aerospace, healthcare, and automotive. The 8th edition explores their integration with smart technologies, offering insights into their transformative potential for modern manufacturing. This section highlights their role in advancing Industry 4.0 and optimizing production workflows.

Smart Manufacturing and Industry 4.0

Smart manufacturing and Industry 4.0 integrate advanced technologies like IoT, AI, and big data to create interconnected, intelligent production systems. This approach enhances efficiency, productivity, and decision-making by enabling real-time monitoring and automation. Cyber-physical systems and digital twins optimize processes, while data analytics drive predictive maintenance and quality control. The 8th edition explores how these innovations reshape manufacturing, fostering agility, scalability, and sustainability across industries like aerospace, automotive, and healthcare.

Environmental and Economic Considerations

Sustainable manufacturing practices reduce environmental impact while optimizing costs, enhancing global competitiveness, and ensuring long-term viability in an increasingly resource-conscious market.

Sustainability in Manufacturing Practices

Sustainability in manufacturing focuses on reducing environmental impact through resource efficiency, renewable energy, and waste reduction. Modern practices integrate eco-friendly materials and energy-efficient technologies to minimize carbon footprints while maintaining productivity. Life-cycle assessments ensure products are designed for recyclability and minimal environmental disruption. Companies adopting sustainable practices not only meet regulatory requirements but also align with global standards, enhancing their reputation and competitiveness in the market. These strategies contribute to long-term environmental stewardship while supporting economic growth.

Economic and Competitive Factors in Global Manufacturing

Global manufacturing is shaped by economic and competitive factors, including cost reduction, innovation, and quality improvement. Companies must adapt to market dynamics, labor costs, and supply chain complexities. Economic challenges drive the adoption of advanced technologies to maintain competitiveness. Understanding global market trends and customer demands is crucial for sustaining profitability. These factors influence manufacturing strategies, emphasizing efficiency, scalability, and adaptability to thrive in a competitive landscape while addressing economic uncertainties and opportunities worldwide.

Learning Resources and Student Support

The 8th edition provides active learning techniques, preview activities, and digital resources to enhance student engagement and understanding of manufacturing engineering and technology concepts.

Active Learning Techniques and Preview Activities

The 8th edition emphasizes active learning through preview activities and interactive exercises, enabling students to engage deeply with manufacturing concepts. These activities are designed to foster critical thinking and problem-solving skills, preparing students for real-world manufacturing challenges. By incorporating case studies and practical applications, the text helps students connect theoretical knowledge with hands-on experience. This approach ensures a comprehensive understanding of manufacturing engineering and technology, making learning both effective and enjoyable;

- Interactive exercises enhance problem-solving abilities;

- Preview activities provide foundational knowledge for each section.

- Real-world applications bridge theory and practice.

Digital Resources and Online Tools for Enhanced Learning

The 8th edition provides digital resources and online tools to enhance learning, including interactive simulations, quizzes, and video tutorials. These resources support active learning by allowing students to visualize complex manufacturing processes and test their understanding. Additionally, online tools offer access to updated materials, case studies, and industry examples, ensuring students are well-prepared for modern manufacturing challenges. These digital aids foster engagement and deepen the understanding of key concepts.

- Interactive simulations for visual learning.

- Quizzes to assess knowledge retention.

- Video tutorials for practical insights.

Future Trends and Industry Outlook

The 8th edition highlights emerging trends like Industry 4.0, additive manufacturing, and automation, shaping the future of manufacturing engineering and technology.

The Evolving Role of Manufacturing Engineering

Manufacturing engineering is evolving rapidly, integrating smart technologies, automation, and data-driven approaches. The 8th edition emphasizes the shift toward Industry 4.0, where engineers must master advanced tools like robotics and IoT. Traditional skills in materials and processes remain critical, but modern engineers now collaborate with AI and machine learning systems. This evolution demands a workforce adept at innovation, sustainability, and efficiency, driving global manufacturing industries forward while addressing complex challenges.

Preparing for the Challenges of the Future

Manufacturing engineering must adapt to emerging technologies like Industry 4;0, smart factories, and sustainable practices. The 8th edition highlights the importance of addressing global challenges, such as resource efficiency and environmental impact. Engineers will need to integrate AI, robotics, and data analytics into workflows. Continuous learning and innovation are essential to stay competitive. The text emphasizes preparing students for these future challenges by fostering a deep understanding of advanced manufacturing systems and their applications.